Ceev thiab yooj yim Fittings (PPSU Khoom)Hloov cov kav dej huv nrog kev nyab xeeb zoo dua thiab ua kom tsis muaj zog. Cov fittings no xa lub neej kev pab cuam tsawg kawg yog 50 xyoo, tiv thaiv corrosion, thiab ua raws li cov qauv dej haus nruj. Kev teeb tsa siv sijhawm ib nrab ntawm lub sijhawm piv rau cov tshuab tooj liab, txo cov nqi thiab kev xav tau ntawm kev ua haujlwm.

Ntsiab Cai

- PPSU Quick thiab Yooj Yim Fittings muab kev nyab xeeb zoo dua thiab ua haujlwm ntev, kav ntev tshaj 50 xyoo yam tsis muaj corrosion los yog cov khoom tsis zoo tso tawm, ua rau lawv zoo tagnrho rau kev tu cev.

- Cov fittings nonruab sai duadua li cov txheej txheem hlau ib txwm muaj, txo cov sijhawm ua haujlwm thiab cov nqi nrog cov txheej txheem yooj yim, tsis muaj cuab yeej txhua tus tuaj yeem ua tau.

- Xaiv PPSU fittings txo qis cov kev xav tau ntawm kev saib xyuas thiab tag nrho cov nuj nqis, muab kev txuag nyiaj mus sij hawm ntev thiab pab cov tub txawg ua raws li cov qauv kev nyiam huv thiab kev nyab xeeb.

Cov kev sib tw hauv kev tu cev thiab kev ua haujlwm kom ceev thiab yooj yim Fittings (PPSU Khoom)

Kev txwv ntawm tooj dag thiab hlau fittings

Cov tooj dag thiab hlau fittings tau ua haujlwm ntev hauv kev tu cev, tab sis kev tshawb fawb qhia txog ntau qhov teeb meem tseem ceeb. Cov khoom siv tooj dag, tshwj xeeb tshaj yog cov uas muaj cov hmoov txhuas, feem ntau ua tsis tiav vim corrosion thiab lead leaching. Txawm tias muaj ntawv pov thawj, cov fittings no tuaj yeem tso cov khoom tsis zoo rau hauv dej, tshwj xeeb tshaj yog nyob rau hauv cov dej ntws siab los yog thaum lub installation tawm tom qab corrosive residues. Corrosion tsis tsuas yog shortens lub neej ntawm cov hlau fittings tab sis kuj ua rau kom cov kev xav tau ntawm kev tu thiab kev pheej hmoo ntawm cov kab mob loj hlob. Cov teeb meem no tau ua rau lub cev tswj hwm kom nruj cov qauv, thawb kev lag luam kom nrhiav kev nyab xeeb dua.

Cov tsoos hlau fittings, tshwj xeeb tshaj yog cov hlau lead, fim nce kev tshuaj xyuas raws li cov kev cai zoo li EU Cov Lus Qhia Txog Kev Haus Dej Dej txwv cov ntsiab lus tso cai.

Sawv Daws Kev Nyab Xeeb thiab Kev Nyab Xeeb

Kev loj hlob ntawm kev paub txog cov kab mob hauv dej thiab kev pheej hmoo kis kab mob tau ua rau muaj kev xav tau kev huv huv hauv cov kav dej. Cov kev tshawb fawb qhia tau tias txawm tias cov kav dej tsis tas yuav lav kev nyab xeeb microbiological. Kev xa khoom tsis tu ncua, kev cia khoom tsis zoo, thiab poob ntawm cov yeeb nkab siab tuaj yeem tso cai rau cov kab mob nkag mus rau hauv lub cev. Cov kev tshawb fawb qhia tau tias ntau lub tsev kho mob, tshwj xeeb tshaj yog nyob rau hauv cov teb chaws tau nyiaj tsawg thiab nruab nrab, tsis muaj kev tu cev txaus. Kev tswj hwm kev tswj hwm, kev koom tes ua thawj coj, thiab cov peev txheej tshwj xeeb tau dhau los ua qhov tseem ceeb rau kev tsim cov qauv kev nyiam huv.

| Kev Tshawb Fawb Xyoo | Lub moj khaum | Cov kev tshawb pom tseem ceeb |

|---|---|---|

| 2011-2019 | LEEJ TWG HHSAF, Global WASH | Kev tswj hwm kev tswj hwm thiab kev coj noj coj ua ua rau muaj cov qauv kev nyiam huv dua; qhov khoob tseem nyob hauv qhov chaw muaj peev txheej tsawg. |

Kev Tshawb Fawb Txog Kev Ua Si Ntev, Txhim Kho Kev Txhim Kho

Cov kws tshaj lij tam sim no tseem ceeb rau cov kev daws teeb meem uas muaj kev ruaj ntseg, kev nyab xeeb, thiab kev ua raws cai. Cov teeb meem tsis tu ncua muaj xws li kev tsim biofilm, corrosion los ntawm cov tshuaj tua kab mob hnyav, thiab tib neeg yuam kev thaum tu. Kev tsom xam kev lag luam qhia tau hais tias kev loj hlob muaj zog hauv kev thov rau cov kav dej txhim khu kev qha, tshwj xeeb tshaj yog cov uas tiv thaiv cov tshuaj degradation thiab tswj kev ncaj ncees ntau xyoo.Ceev thiab yooj yim Fittings(PPSU Khoom) hais txog cov kev xav tau no nrog cov tshuaj tiv thaiv zoo tshaj plaws, kev ua haujlwm tsis zoo ntawm lub cev, thiab kev ua haujlwm ntev, ua rau lawv xaiv qhov kev nyiam huv rau cov kav dej niaj hnub.

Qhov zoo ntawm PPSU Quick thiab Yooj Yim Fittings (PPSU Khoom)

Mechanical thiab Chemical Strength

PPSU qhia tau tshwj xeeb ntawm cov tshuab thiab tshuaj lom neeg lub zog, ua rau nws nyiam cov khoom siv rau kev thov cov kav dej. Cov kws tshawb fawb tau pom tias PPSU ua tau zoo dua lwm cov yas yas xws li polysulfone thiab polyimide hauv ob qho tib si cuam tshuam thiab tshuaj lom neeg ruaj khov. Lub zog no tau tshwm sim los ntawm nws cov qauv molecular tshwj xeeb, uas suav nrog tetramethylbiphenol moieties. Cov yam ntxwv ntawm cov qauv no ua rau kom lub ntim pub dawb thiab cov saw rigidity ntawm cov polymer, txhim kho ob qho tib si thauj khoom thiab cov khoom siv tawv.

- PPSU tswj qhov kub thiab txias thiab qhov ruaj khov, txawm tias nyob rau hauv qhov kev ntxhov siab tas mus li.

- Cov khoom siv tiv thaiv hluav taws xob kom tsis muaj menyuam, alkalis, thiab cov kua qaub tsis muaj zog, uas muaj nyob rau hauv ib puag ncig huv.

- PPSU's robust polymer matrix txhawb siab permeability thiab sorption coefficients rau gases xws li CO2, qhia superior tshuaj stability.

Cov neeg tsim khoom feem ntau xaiv PPSU rau cov khoom siv kho mob thiab cov dej kub fittings, qhov twg ob qho tib si ua haujlwm ntev thiab tshuaj lom neeg yog qhov tseem ceeb.Ceev thiab yooj yim Fittings(PPSU Material) leverage cov khoom no kom xa cov kev ua tau zoo hauv ib puag ncig uas xav tau ob qho tib si lub zog thiab kev ua haujlwm.

Certified Safety thiab Regulatory Compliance

Kev nyab xeeb thiab kev ua raws cai yog qhov tseem ceeb tshaj plaws hauv cov kav dej niaj hnub. PPSU fittings tau ua tiav ntau daim ntawv pov thawj tseem ceeb, lees paub tias lawv tsim nyog rau cov ntawv thov tseem ceeb. Cov lus hauv qab no qhia txog cov ntawv pov thawj tseem ceeb thiab cov qauv ua tau raws li PPSU fittings:

| Ntawv pov thawj / Standard | Paub meej thiab xwm txheej |

|---|---|

| UL Daim Ntawv Pov Thawj (UL 1821) | Ua tiav rau qhov tshwj xeeb PPSU-PEX haum ua ke |

| FM Ntiaj Teb | Pom zoo rau lub teeb muaj kev phom sij; kev ntsuas hluav taws tag nrho tseem tab tom tos |

| NFPA 13 | Yuav tsum tau kev tso cai tshwj xeeb rau cov tshuab tsis yog hlau |

| Cov European Standard EN 12845 | Tso cai siv PPSU fittings hauv pre-action sprinkler systems |

| DIN 14800 Kev Xeem | Dhau hauv German automotive cog rau ESFR system siv |

Cov ntawv pov thawj no qhia tau tias PPSU fittings ua tau raws li kev nyab xeeb thiab kev ua tau zoo. Kev tswj hwm lub cev hauv Tebchaws Meskas thiab Europe lees paub qhov kev ntseeg siab ntawm PPSU hauv kev tiv thaiv hluav taws thiab cov dej haus. Quick thiab Easy Fittings (PPSU Material) pab cov kws tshaj lij ua raws li cov qauv kev hloov pauv, txo cov kev pheej hmoo ntawm kev tswj hwm teeb meem thiab txhawb kev noj qab haus huv rau pej xeem.

Corrosion Resistance thiab Extended Lifespan

Corrosion tseem yog ib qho kev txhawj xeeb tseem ceeb hauv cov kav dej ib txwm siv, feem ntau ua rau cov dej xau, kev sib kis, thiab kev kho nqi kim. PPSU cov qauv tshuaj muaj txiaj ntsig zoo rau kev tiv thaiv corrosion, txawm tias thaum raug cov tshuaj tua kab mob lossis cov dej tsis zoo. Kev sim kuaj pom tseeb tias PPSU fittings tswj lawv cov chemistry saum npoo thiab cov khoom siv kho tshuab nyob rau lub sijhawm ntev.

| Kev ntsuas / ntsuas | Kev piav qhia | Cov kev tshawb pom tseem ceeb txhawb kev ua haujlwm ntev ntawm PPSU Fittings |

|---|---|---|

| XPS Elemental Composition (Carbon & Oxygen) | Ntsuas ntau tshaj 212 hnub thiab extrapolated mus rau 417 hnub nyob rau hauv ambient huab cua thiab tsaus ntuj | Cov pa roj carbon thiab cov pa oxygen hloov pauv tsuas yog ~ 1 atom% los ntawm 212 mus rau 417 hnub, qhia txog qhov tsawg kawg ntawm chemistry hloov lub sijhawm |

| Carbon Functionality Distribution (C=O, (C=O)–O, C–S, C–C) | Kev tshuaj xyuas nyob rau hauv ntau yam kev kho mob ntshav plasma | Oxidation khoom tsim thiab ruaj khov; hnyav plasma tej yam kev mob yuav tsum tau rau saw scission; Qhov saum npoo oxidation tseem ruaj khov nrog tsuas yog hloov me ntsis thaum lub sijhawm |

| Wettability (Kev sib cuag lub kaum sab xis) | Sib cuag cov ces kaum ntsuas rau cov plasma kho thiab tsis kho cov qauv | Plasma kho PPSU qhia tau hais tias muaj kev ntub dej siab (tej me me absorbed sai), qhia qhov hloov kho qhov chaw ruaj khov; Cov qauv siv hydrophobic muaj lub kaum sab xis ~ 130 ° |

| Sijhawm Extrapolation ntawm Nto Khoom | Cov ntsiab lus carbon thiab oxygen haum rau cov qauv diffusion thiab ntxiv rau 10,000 teev (417 hnub) | Cov khoom saum npoo yuav txo qis logarithmically tab sis yuav siv sij hawm ntau pua txhiab xyoo los ua kom rov qab los, ua kom pom kev ua haujlwm ntev dua li lub neej xav tau |

Cov txiaj ntsig no qhia tau tias PPSU fittings tiv thaiv cov tshuaj lom neeg thiab lub cev degradation, ua kom lub neej ua haujlwm ntev. Cov khoom siv ruaj khov nyob rau hauv oxidative thiab ib puag ncig kev ntxhov siab txhais tau hais tias Quick thiab Yooj Yim Fittings (PPSU Khoom) tuaj yeem xa cov kev ua tau zoo rau ntau xyoo, txawm tias muaj kev nyuaj.

PPSU vs. Cov khoom siv niaj hnub

PPSU muaj ntau yam zoo dua li cov khoom siv xws li tooj dag thiab tooj liab. Thaum cov hlau fittings feem ntau raug kev txom nyem los ntawm corrosion, lead leaching, thiab biofilm tsim, PPSU tseem inert thiab ruaj khov. Cov ntsiab lus hauv qab no qhia txog qhov sib txawv tseem ceeb:

- PPSU tsis corrode los yog tso cov khoom tsis zoo rau hauv dej, txhawb nqa cov qauv kev nyiam huv dua.

- Cov khoom no tuaj yeem rov ua kom tsis muaj menyuam thiab raug cov tshuaj ntxuav, tsis zoo li cov hlau uas tuaj yeem degrade lossis qhov dej dhau sijhawm.

- PPSU fittings tswj lawv cov neeg kho tshuab kev ncaj ncees thiab cov khoom saum npoo av tau ntau xyoo, txo qhov xav tau kev hloov pauv ntau zaus.

Cov kws tshaj lij uas xaiv PPSU tau txais txiaj ntsig los ntawm cov kav dej uas ua tau raws li niaj hnub kev nyab xeeb, kav ntev, thiab kev nyiam huv. Quick thiab Yooj Yim Fittings (PPSU Khoom) tau teeb tsa tus qauv tshiab rau kev ntseeg tau, pab cov chaw pov thawj yav tom ntej rau lawv cov vaj tse.

Kev teeb tsa thiab tus nqi txiaj ntsig ntawm kev ceev thiab yooj yim Fittings (PPSU Khoom)

Txhim khu kev txhim kho txheej txheem

Installers tau txais txiaj ntsig los ntawm kev ua haujlwm sai dua thaum sivCeev thiab yooj yim Fittings (PPSU Khoom). Cov fittings no yuav tsum tsis muaj kev sib txuas, xov, lossis cov cuab yeej hnyav. Cov txheej txheem sib dhos yog cov cuab yeej tsis pub dawb thiab nkag siab, tso cai rau cov neeg ua haujlwm tsawg dua kom ua tiav cov kev sib raug zoo. Piv txwv li, 10-meter yeeb nkab khiav tuaj yeem ua tiav hauv 30 feeb nrog PPSU fittings, thaum tooj liab kav yuav siv li ib teev. Cov lus hauv qab no qhia txog kev sib piv lub sijhawm teeb tsa:

| Hom khoom | Lub sij hawm txhim kho piv rau hlau |

|---|---|

| PEB PEX | 60% sai dua |

| CPVC | 30% sai dua |

| Hlau | Lub hauv paus |

Qhov kev ua tau zoo no txo cov sijhawm ua haujlwm thiab txo qis kev cuam tshuam hauv kev tsim kho tshiab thiab kho dua tshiab.

Cov nqi zog qis dua thiab kev saib xyuas

PPSU cov tshuab xa cov nyiaj txuag tseem ceeb tshaj lawv lub neej.

- Tus nqi lifecycle ntawm PPSU PEX fittings yog $8.20 ib ko taw, qis dua hlau ntawm $12.50 ib ko taw.

- Cov ntaub ntawv pov thawj qhia tau hais tias qhov txo qis ntawm 40% hauv kev saib xyuas qhov xwm txheej piv rau cov hlau galvanized.

- Lub sij hawm txhim kho yog 60% sai dua cov hlau, uas txo cov nqi zog.

- PPSU fittings tiv thaiv corrosion, yog li kev saib xyuas ntsig txog kev xau lossis nplai yog qhov tsawg.

- Cov tswv tsev txuag tau ntawm $ 500 thiab $ 1,000 tshaj 20 xyoo vim muaj kev hloov pauv tsawg dua thiab kho dua tshiab.

Cov nyiaj khaws cia no ua rau PPSU cov txheej txheem ua lag luam ntse rau ob qho tib si kev lag luam thiab thaj chaw nyob.

Tswv yim nqi rau cov kws tshaj lij

Cov kws tshaj lij xaiv PPSU fittings rau lawv qhov kev ua tau zoo thiab ntau yam.

| Performance Aspect | Paub meej & Metrics |

|---|---|

| Kev ceev ceev | 16 bar ntawm 23 ° C, 10 bar ntawm 80 ° C |

| Lub neej ntev | Tshaj 20 xyoo hauv dej kub, 50+ xyoo nrog kev teeb tsa kom raug |

| Leak Rates | <0.01 × DN mm/min, ua tau raws li API 598 tus qauv |

| Installation efficiency | Cov cuab yeej-dawb sib dhos, 50% sai dua tooj liab |

| Kev sib haum xeeb | Ua haujlwm nrog PEX, CPVC, thiab cov kav dej hlau |

| Kev tu | Tsis xav tau kev kho corrosion, yooj yim scale tshem tawm |

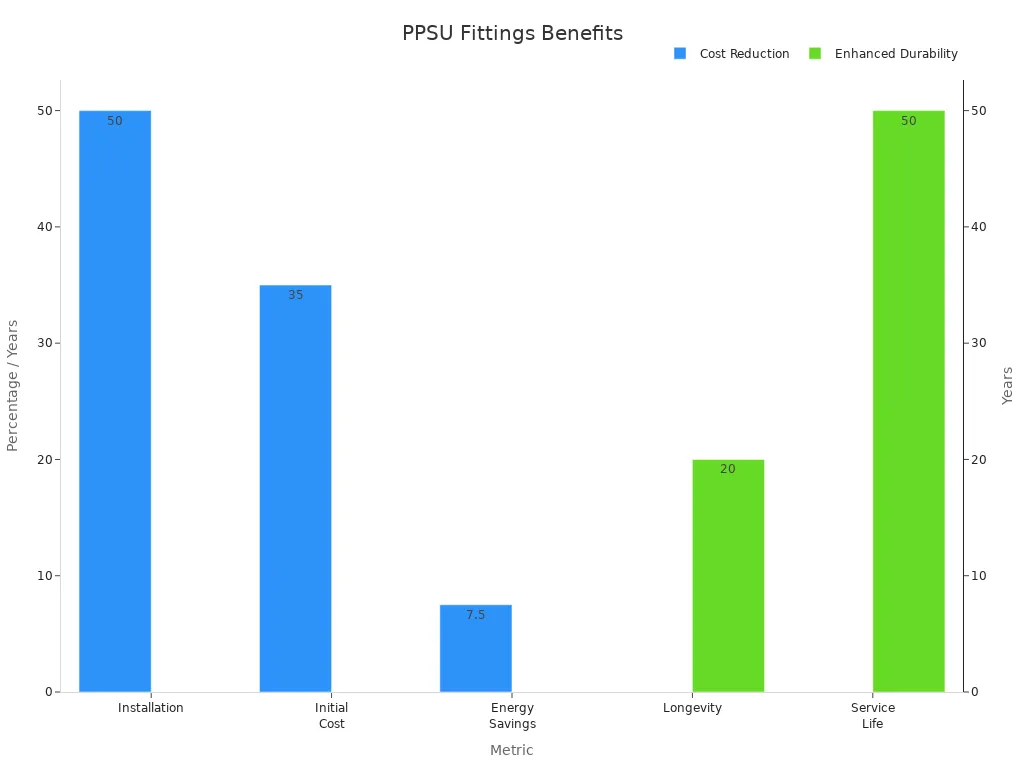

| Nqi-zoo | 30-40% tus nqi pib qis dua tooj liab, txuag hluav taws xob ntawm 5-10% |

Stephan Müller, tus kws tshaj lij, sau tseg tias PPSU lub zog muaj zog, tiv thaiv tshav kub, thiab ua raws li EU cov qauv nruj ua rau nws zoo tagnrho rau cov dej haus. Cov kws tshaj lij tau txais kev sib tw los ntawm kev xa cov kev nyab xeeb dua, siv tau ntev dua, thiab cov nqi siv hluav taws xob ntau dua.

Ceev thiab Yooj Yim Fittings (PPSU Khoom) tsa lub bar rau kev tu cev. Lawv xa cov kev nyab xeeb tsis sib xws, kev ua haujlwm ntev, thiab kev teeb tsa yooj yim. Ntau tus kws tshaj lij tam sim no xaiv cov khoom siv no kom ua tau raws li cov qauv nruj. Cov pab pawg xav txog pem hauv ntej cia siab rau lawv rau yav tom ntej-pov thawj cov kav dej thiab ua kom ntseeg tau tias kev ua tau zoo.

FAQ

Dab tsi ua rau PPSU fittings haum rau cov dej haus?

PPSU fittings tiv thaiv corrosion thiab tsis leaching cov teeb meem tshuaj. Lawv ua tau raws li cov qauv thoob ntiaj teb nruj me ntsis rau kev nyab xeeb dej thiab kev nyiam huv.

Cov kws tshaj lij puas tuaj yeem nruab PPSU cov khoom siv ceev thiab yooj yim yam tsis muaj cov cuab yeej tshwj xeeb?

Yog lawm. Installers tautxuas PPSU fittings los ntawm tes. Cov txheej txheem tsis tas yuav tsum tau soldering, threading, lossis cov cuab yeej hnyav.

Ntev npaum li cas PPSU qhov ceev thiab yooj yim fittings nyob rau hauv cov ntawv thov raug?

Feem ntau PPSU fittings xa cov kev pab cuam lub neej ntawm 50 xyoo lossis ntau dua, txawm tias nyob rau hauv qhov xav tau. Kev tshuaj xyuas tsis tu ncua pab ua kom pom kev ua haujlwm zoo.

Post lub sij hawm: Jun-26-2025